our workmanship

We combine skillful Craftsmanship with High Technology for the production of seamless knitwear

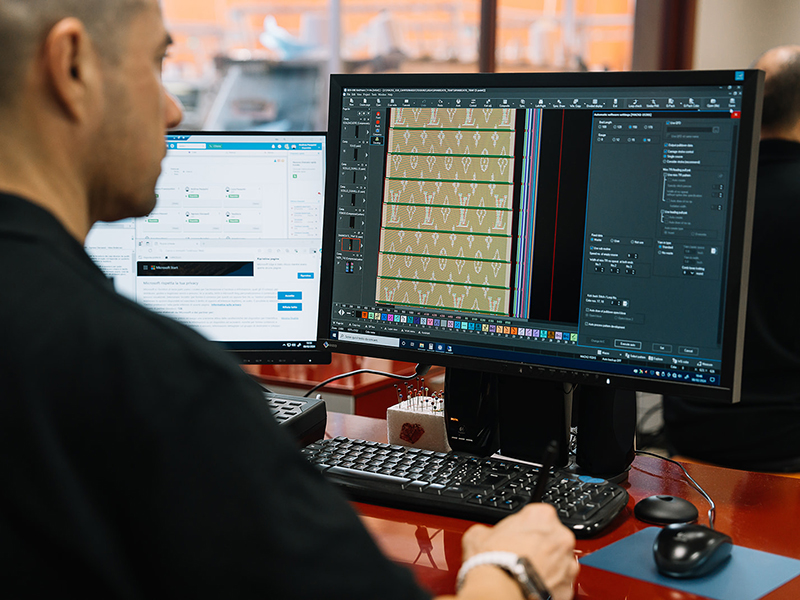

Programmers‘ room

Our production process begins in the programming room, where our expert programmers use Shima software to design the technical drawings of our garments. Thanks to this advanced software, it is possible to simultaneously create multiple parts of the garment, including the front, back, and sleeves.

This allows us to produce garments with meticulous and detailed workmanship. The result is a finished product that comes out of the machine ready to wear, without the need for additional stitching.

machinery

Our machinery is capable of producing all gauges from 18 to 2.5 and allows for the completion of two stages in one: production and assembly. This technology enables the creation of garments with pouches or machine-made pockets, devoré processes, integrated hoods, and enhanced with links, cables, inlays, ribs, and striped garments.

These advanced machines can create extremely detailed patterns.

This technology allows us to offer high-quality products with a variety of innovative textures and designs.

MACHINERY LIST

| 11 SWG-X 173 F.15 | Produzione di capi completi senza cuciture anche in coste, links, trecce, capi rigati ed intarsio in finezza 16 / 18 |

| 4 SWG-X 173 F.12 | Per la produzione di capi completi senza cuciture, finezza 12 anche in coste, links, trecce, capi rigati ed intarsio |

| 2 MACH X 173 F.15 | Per la produzione di capi completi senza cucitura, con stesse caratteristiche di lavorazione dei modelli SWG X ma con migliori prestazioni |

| 2 NEW SES-S WG F.10 | 2 NEW SES-S WG F.10 Per la produzione di capi completi senza cucitura, in finezza 5 |

| 1 SWG – V F.5 | Per la produzione di capi completi senza cucitura, in finezza 5 |

| 2 SWG-041 | Per la realizzazione di accessori in finezze sottili come guanti e calzini tridimensionali, cravatte, sciarpe con frange da macchina ecc. |

| 3 MACH X 173 F. 18 | Per la produzione di capi completi senza cucitura, con stesse caratteristiche di lavorazione dei modelli SWG X ma con migliori prestazioni |

| 1 MACH 2 S F. 16 | |

| 1 FIRST 154 F.21 | |

| 4 COMPUTER APEX 3 |

the human element

The Human Element: A fundamental aspect of our production process is the human element; in fact, in quality control and the use of specific machinery such as the linker, precision and manual skill are essential to ensure the success of the garment. Furthermore, the human contribution is present throughout our company and represents what sets us apart. This allows us to create very personal relationships with our customers, reflecting this care and attention in the production of every garment.

additional services

Our entirely in-house production has driven us to seek technological innovations and specific machinery, allowing us to offer our customers a finished product that reduces costs, time, and waste of resources and raw materials. Below, we present our exclusive machinery, ideal for those customers seeking a unique and sustainable product.

Yarn Conditioning Room

This humidified room is maintained at 90% humidity 24/7 to regenerate the fibers and make them more workable, thus preventing damaged and non-compliant garments.

Twister

This machine allows for the creation of customized yarns by combining different types of materials, such as wool or cashmere with lycra, lurex, or others. In this way, we are able to meet the specific needs of each customer.

air splicer

This machine uses compressed air to weld the thread without needing to knot the two ends, allowing continuous processing without thickening or bar breaks.

linking machine

Machines in various gauges that allow for the seaming of collars, cuffs, flaps… and all those details added outside of seamless weaving.

hydrocarbon

A machine that allows for dry cleaning, also known as dry milling, because its lower aggressiveness compared to the hyperchlorine machine allows the garment to be purged of various oils or fats typical of untreated yarn.

Miele Washing Machine

A computerized MIELE washing machine with customized programs for each type of yarn, modifiable from a computer as neededLavatrice computerizzata con programmi personalizzati per ogni tipologia di filato e modificabili da computer di volta in volta a seconda delle necessità.

LA TRAMA s.r.l.

Registered office:

via Nevola, 124

60013 Corinaldo (AN)

Showroom:

via Piani D’Appresso, 5/C

60010 Ostra Vetere (AN)

Phone:

+39 071 679 167

+39 071 964 271

Email:

[email protected]